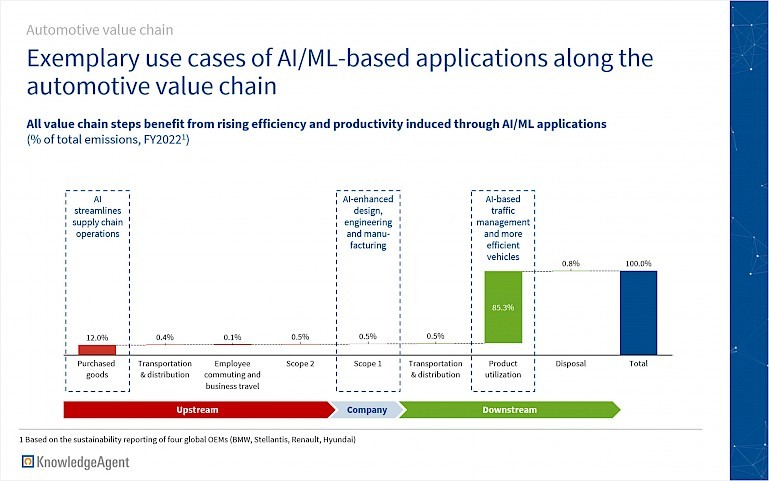

Smart manufacturing as well as artificial intelligence (AI) and machine learning (ML) are revolutionizing industries worldwide, and the automotive sector is no exception. In our blog post ‘AI driving sustainability in the automotive industry’, we explored the impact of AI/ML on greenhouse gas (GHG) emissions within the automotive value chain. We highlighted that scope 1 emissions reductions are achieved indirectly through AI/ML-driven improvements in efficiency and productivity, leading to lower costs and reduced resource consumption.

Today's blog post will take a closer look at the engineering and production process, exploring the reduction and improvement potential of AI-enhanced design, engineering, and manufacturing.

AI and Smart Manufacturing

AI's relevance in automotive manufacturing, particularly in smart manufacturing, lies in its ability to process vast amounts of data, learn from it, and make informed decisions. This optimizes every aspect of manufacturing, from design and engineering to production processes, assembly lines, quality control, supply chain management, and worker safety.

Design and Engineering

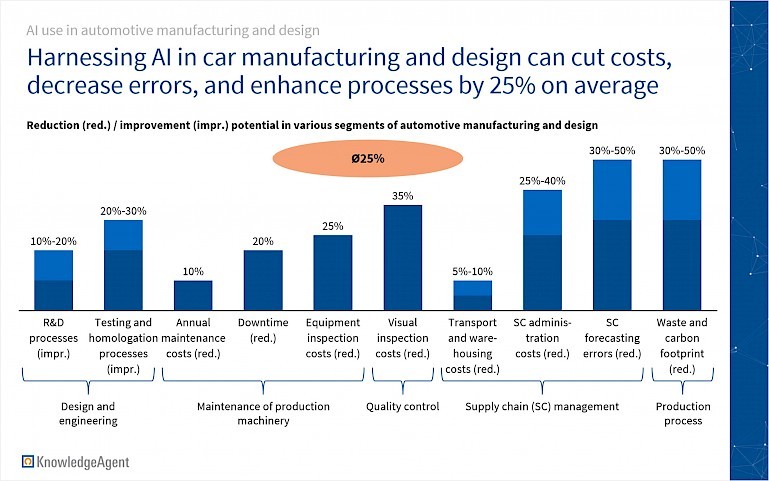

AI accelerates the R&D process by rapidly analyzing data from crash tests, simulations, and real-world vehicle use. For instance, digital twin technology exemplifies AI's profound impact. This virtual modeling allows for exhaustive testing, modifications, and analyses of vehicles and their components in a cost-effective and time-efficient manner. By simulating real-world scenarios, automotive engineers can predict performance outcomes, reduce defects, and accelerate the development cycle, ensuring that the final product exceeds market expectations. Research by McKinsey shows that employing generative AI in design and development can improve R&D processes by 10% to 20% and testing and homologation processes by 20% to 30%.

Customization and Product Innovation

AI is revolutionizing product innovation by enabling faster, more efficient design processes. Advanced AI algorithms allow manufacturers to simulate and test thousands of design variations quickly. This speeds up the innovation cycle and allows for exploring more creative and efficient design solutions. For instance, AI-driven tools can predict how design changes impact a vehicle's performance, from fuel efficiency to safety ratings, enabling engineers to optimize designs before building prototypes.

AI also opens new avenues for customer engagement and market differentiation, allowing manufacturers to offer personalized options without significantly slowing down production. By drawing on historical interactions and purchases, AI customizes insights for each consumer, catering to unique requirements. This enables businesses to leverage past data to forecast market trends.

Operational Processes

On the operational side, AI technologies provide manufacturers with unprecedented insights into their production processes. By analyzing data from across the manufacturing lifecycle, such as lead times, material quantities, cycle times, errors, and downtime, AI can identify bottlenecks, predict equipment failures, and recommend optimizations. This deep operational insight allows manufacturers to make informed decisions that reduce waste, lower costs, and enhance productivity.

Predictive Maintenance

AI-driven predictive maintenance can forecast when machinery or vehicle components are likely to fail, significantly reducing downtime and maintenance costs. These AI systems leverage Internet of Things (IoT) sensors to monitor machinery in real-time, tracking data like temperature, vibration, and lubrication. This enables AI to detect potential issues before they occur. McKinsey research suggests that AI-enhanced predictive maintenance can lead to a 10% reduction in annual maintenance costs, a 20% decrease in downtime, and a 25% cut in inspection costs.

Robotic Assembly

AI-driven robots have significantly increased the efficiency of automotive production lines. For instance, at BMW's Spartanburg facility in South Carolina, U.S., AI-managed robots are used in the welding process in the body shop, attaching 300-400 metal studs onto each vehicle frame, amounting to about half a million studs daily.

Quality Control

AI algorithms are used for component inspection and quality control, detecting and correcting defects and ensuring high standards. BMW, for example, uses autonomous machine vision technology to inspect and analyze tiny imperfections in paintwork and bodywork. AI eliminates pseudo-defects through a self-learning neural network that accesses approximately 100 real images for each feature. Ford, on the other hand, uses image recognition to detect wrinkles in car seats, improving the production process. McKinsey estimates that productivity in visual quality inspection could be increased by up to 50%. Moreover, AI cross-references vehicle order information with real-time images of model labels on newly manufactured cars, quickly spotting any differences, thereby enhancing BMW's production quality control.

Supply Chain Management and Intralogistics

According to McKinsey, machine learning can lead to a 30% to 50% reduction in supply chain forecasting errors, 5% to 10% lower transport and warehousing costs, and 25% to 40% lower costs related to supply chain administration. Ford uses AI to predict and analyze supply chain disruptions, improving material flow and reducing downtime. AI algorithms can forecast parts shortages and suggest alternative suppliers, enhancing resilience against global supply chain challenges. BMW’s Steyr plant uses AI to enhance logistics by eliminating needless movements of empty containers on conveyor belts as they move through a camera station.

Sustainability / Waste and Carbon Footprint

Incorporating AI into automotive manufacturing and design aligns with the industry's growing commitment to sustainability. Smart manufacturing processes optimized by AI can lead to more efficient use of resources, reduced waste, and a decreased carbon footprint of vehicle production. Research indicates potential reductions of 30-50%. By leveraging AI for better design and manufacturing efficiency, the automotive industry is moving toward a more sustainable future. Volkswagen has implemented AI to optimize energy use in its plants, significantly reducing CO2 emissions and achieving an annual savings potential of 800,000 euros in its Wolfsburg, Germany plant alone, using ML and digital twins to enhance the energy efficiency of air compressors. Renault's adoption of AI analytics also showcases the potential for energy-efficient manufacturing. By implementing measures like sensor-regulated warm-air curtains and speed variators on electric motors, Renault has achieved significant energy savings, e.g., cutting heat loss by 80% and saving around 80,000 euros annually.

Worker Safety

AI and robotics can also be helpful in improving safety in manufacturing by performing dangerous tasks. AI aids in tasks that cause common injuries like musculoskeletal disorders by utilizing autonomous vehicles for risky activities. Toyota, for example, partners with startup Invisible AI to introduce motion capture technology across its North American plants to enhance efficiency and safety. The AI system tracks workers' movements without direct supervision or wearable sensors, identifying process improvements and real-time task verification.

Conclusion

In conclusion, as the automotive industry moves into the second half of 2024 and beyond, AI's influence on manufacturing and design heralds a new chapter of innovation and growth. It will be exciting to see the advancements that generative AI, in particular, will bring to automotive production. Automotive industry professionals must leverage market research and competitive intelligence services to navigate these transformations. Understanding AI integration throughout the value chain and its implications empowers businesses to make informed decisions, innovate strategically, and achieve a competitive advantage.

With extensive expertise in value chain analysis, our market research and competitive intelligence services can support your journey through the AI revolution in the automotive industry. To learn more, contact our Automotive & New Mobility team.

Sources

-

McKinsey & Company, Peter Cholewinski, Wolf Richter, Matthias Roggendorf, Andreas Venus, Martin Kellner & Andreas Tschiesner, 09/02/2024, Automotive R&D transformation: Optimizing gen AI’s potential value, https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/automotive-r-and-d-transformation-optimizing-gen-ais-potential-value, accessed 08/05/2024

-

Microsoft, Dominik Wee, 29/01/2024, Learning from CES 2024: 5 ways AI is reshaping the future of mobility, https://www.microsoft.com/en-us/industry/blog/manufacturing-and-mobility/2024/01/29/learning-from-ces-2024-5-ways-ai-is-reshaping-the-future-of-mobility/, accessed 08/05/2024

-

Aicadium, 13/12/2023, How BMW is using AI to improve its manufacturing processes, https://aicadium.ai/how-bmw-is-using-ai-to-improve-its-manufacturing-processes/, accessed 08/05/2024

-

Google Cloud Blog, Umesh Vemuri & Jennifer Werthwein, 06/12/2023, Five ways artificial intelligence is accelerating the auto industry's green shift, https://cloud.google.com/blog/topics/sustainability/cop28-artificial-intelligence-accelerates-auto-industrys-green-shift?hl=en, accessed 08/05/2024

-

Simplilearn, Stuart Rauch, 28/11/2023, AI in the Automotive Industry: A 2024 Outlook, https://www.simplilearn.com/ai-in-automative-article, accessed 08/05/2024

-

Renault Group, 24/10/2023, Energy performance: the Ecogy portal keeps consumption under control at Renault Group’s plants, https://www.renaultgroup.com/en/news-on-air/top-stories-2/energy-performance-the-ecogy-portal-keeps-consumption-under-control-at-renault-groups-plants/, accessed 08/05/2024

-

Foley & Lardner LLP, Peter Loh, 01/08/2023, Smart Manufacturing Is the Future of Automotive Manufacturing, https://www.foley.com/insights/publications/2023/08/smart-manufacturing-future-automotive/, accessed 08/05/2024

-

CNBC, Andrea Day, 21/07/2023, How BMW uses A.I. to make vehicle assembly more efficient, https://www.cnbc.com/2023/07/21/how-bmw-uses-ai-to-make-vehicle-assembly-more-efficient.html, accessed 08/05/2024

-

Environmental Chemistry Letters, Chen et al., 13/06/2023, Artificial intelligence-based solutions for climate change: a review, https://link.springer.com/article/10.1007/s10311-023-01617-y, accessed 08/05/2024

-

LinkedIn Pulse, Niraj Kumar, 13/06/2023, Generative AI and the Automotive Industry: A Roadmap for Innovation and Impact, https://www.linkedin.com/pulse/generative-ai-automotive-industry-roadmap-innovation-impact-kumar/, accessed 08/05/2024

-

Royale International, Ted Baker, 09/06/2023, The Role of Artificial Intelligence in Automotive Manufacturing, https://www.royaleinternational.com/2023/06/the-role-of-artificial-intelligence-in-automotive-manufacturing/, accessed 08/05/2024

-

Supply Chain Dive, Michelle No, 08/05/2023, How manufacturers are using AI to improve worker safety, https://www.supplychaindive.com/news/ai-manufacturing-workplace-safety-improvement/649575/, accessed 08/05/2024

-

Tagesspiegel, Jana Kugoth, 05/04/2023, Künstliche Intelligenz bei VW

-

Automotive News Europe, Larry P. Vellequette, 04/05/2022, Toyota finds a way to make its kaizens faster, https://europe.autonews.com/automakers/toyota-launches-ai-devices-assembly-line-boost-efficiency, accessed 08/05/2024

-

IoT Times, Emily Newton, 12/01/2022, How Are AI and Robotics Increasing Manufacturing Quality and Efficiency?, https://iot.eetimes.com/how-are-ai-and-robotics-increasing-manufacturing-quality-and-efficiency/, accessed 08/05/2024

-

Manufacturing, Sam Scane, 13/11/2020, BMW: Quality Control Through Artificial Intelligence, https://manufacturingdigital.com/ai-and-automation/bmw-quality-control-through-artificial-intelligence, accessed 08/05/2024

-

BMW, 15/07/2019, Fast, efficient, reliable: Artificial intelligence in BMW Group Production, https://www.press.bmwgroup.com/global/article/detail/T0298650EN/fast-efficient-reliable:-artificial-intelligence-in-bmw-group-production?language=en, accessed 08/05/2024

-

Forbes, Bernard Marr, 17/05/2019, The Amazing Ways The Ford Motor Company Uses Artificial Intelligence And Machine Learning, https://www.forbes.com/sites/bernardmarr/2019/05/17/the-amazing-ways-the-ford-motor-company-uses-artificial-intelligence-and-machine-learning/, accessed 08/05/2024

-

CIO Dive, Naomi Eide, 05/04/2019, Ford is a mobility company with an AI 'core competency,' CTO says, https://www.ciodive.com/news/ford-cto-AI-mobility-autonomous/552117/, accessed 08/05/2024

-

IndustryWeek, Javier Jimenez, 22/05/2018, 5 Ways Artificial Intelligence Can Boost Productivity, https://www.industryweek.com/technology-and-iiot/article/22025683/5-ways-artificial-intelligence-can-boost-productivity, accessed 08/05/2024

-

McKinsey & Company, Matthias Breunig, Matthias Kässer, Heinz Klein, & Jan Paul Stein, 02/10/2017, Building smarter cars with smarter factories: How AI will change the auto business, https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/building-smarter-cars, accessed 08/05/2024

-

McKinsey & Company, Harald Bauer, Gérard Richter, Jan Wüllenweber, Matthias Breunig, Dominik Wee & Heinz Klein, 19/04/2017, Smartening up with Artificial Intelligence (AI) – What’s in it for Germany and its Industrial Sector?, https://web.archive.org/web/20180416083656/http://www.mckinsey.de/files/170419_mckinsey_ki_final_m.pdf, accessed 08/05/2024 (archived version)