In today's rapidly evolving world, sustainability has become a critical concern for businesses across industries. The semiconductor industry, which drives technological advancements and powers countless devices, is no exception. As the demand for high-performance chips continues to rise due to new emerging technologies such as AI and IoT, so does the need for sustainable practices. Embracing sustainability not only helps companies reduce their climate footprint but also enhances their reputation, attracts investors, and fosters long-term profitability.

Semiconductor manufacturing as energy and resources intensive production process

Although semiconductors contribute to climate neutrality as they are essential to EV’s or solar arrays for example, there are some urgent sustainability problems chip fabrication plants are facing: energy consumption, process gases, water usage, and waste disposal. Overall, fabs have a large carbon footprint with significant scope 1 greenhouse gas emissions (GHG) of manufacturers.

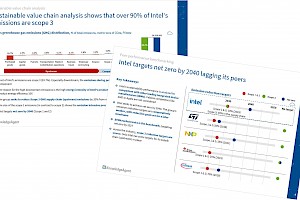

Semiconductor manufacturing processes are energy-intensive, resulting in significant scope 1&2 GHG emissions. TSMC, the world’s largest chipmaker alone uses almost 5% of all Taiwan’s electricity. Other discrete manufacturing industries, such as the automotive or aerospace sectors, need significantly less energy to generate revenue.

Moreover, the industry requires vast amounts of water - a single fab can withdraw 10 million gallons of water per day which is equivalent to the daily water consumption of a small city of about 120,000 inhabitants. What makes this even more challenging is that many semiconductor plants are sited in regions of high water-stress. Besides that, water use and energy sources are correlated as wastewater management processes require a high energy consumption.

The semiconductor industry generates a substantial amount of hazardous waste since the production of chips involves over 400 chemical products (process gases). Mismanagement of chemical solvents, sludge, and contaminated equipment can harm the environment. Along with hazardous waste which results from production processes, the disposal of electronic waste is a growing concern as well.

Current Sustainability Trends

Many semiconductor companies have implemented strategies for climate protection in the areas of renewable energy use, process improvements, alternative chemicals, and destruction technologies.

A central approach to protect natural resources is to capture more data and to use machine learning. This results in an increased efficiency of fabs through the regulation of air and water temperature. Many chip makers already integrated water resources management programs to address planning for water quality, quantity, and resource control. With smart control systems in several IoT devices used to control water as well as heating and lighting, vast amounts of energy can be saved, reducing scope 1 & 2 emissions.

To optimize energy supply, semiconductor companies develop new off-grid power sources that rely on green technologies such as photovoltaics or fuel cells. A better access to renewable energy helps chipmakers to reduce their carbon footprint, lowering scope 2 emissions in energy procurement. Especially in Europe, renewable energies account for 31% of all electricity generation types, which is a crucial factor for semiconductor companies in deciding where they should build new fabs.

To reduce scope 1 emissions that are involved in the production processes of semiconductors chip companies have switched to alternative input gases. There is also the possibility to recycle gases and by-products as well as the option to increase gas abatement with point-of-use or point-of-area systems.

Regarding the waste disposal problems the industry faces, chipmakers are increasingly applying circular economy measures. An alternative strategy to reduce waste upfront involves minimizing the material use including using thinner wafers or reducing the thickness of dielectric layers.

As in general, customers are willing to pay more for climate-friendly products and as climate measures are of great significance for investors, semiconductor manufacturers will be forced to follow the sustainability trends in the industry.

Case Study: Sustainable value chain analysis and peer benchmarking of Intel

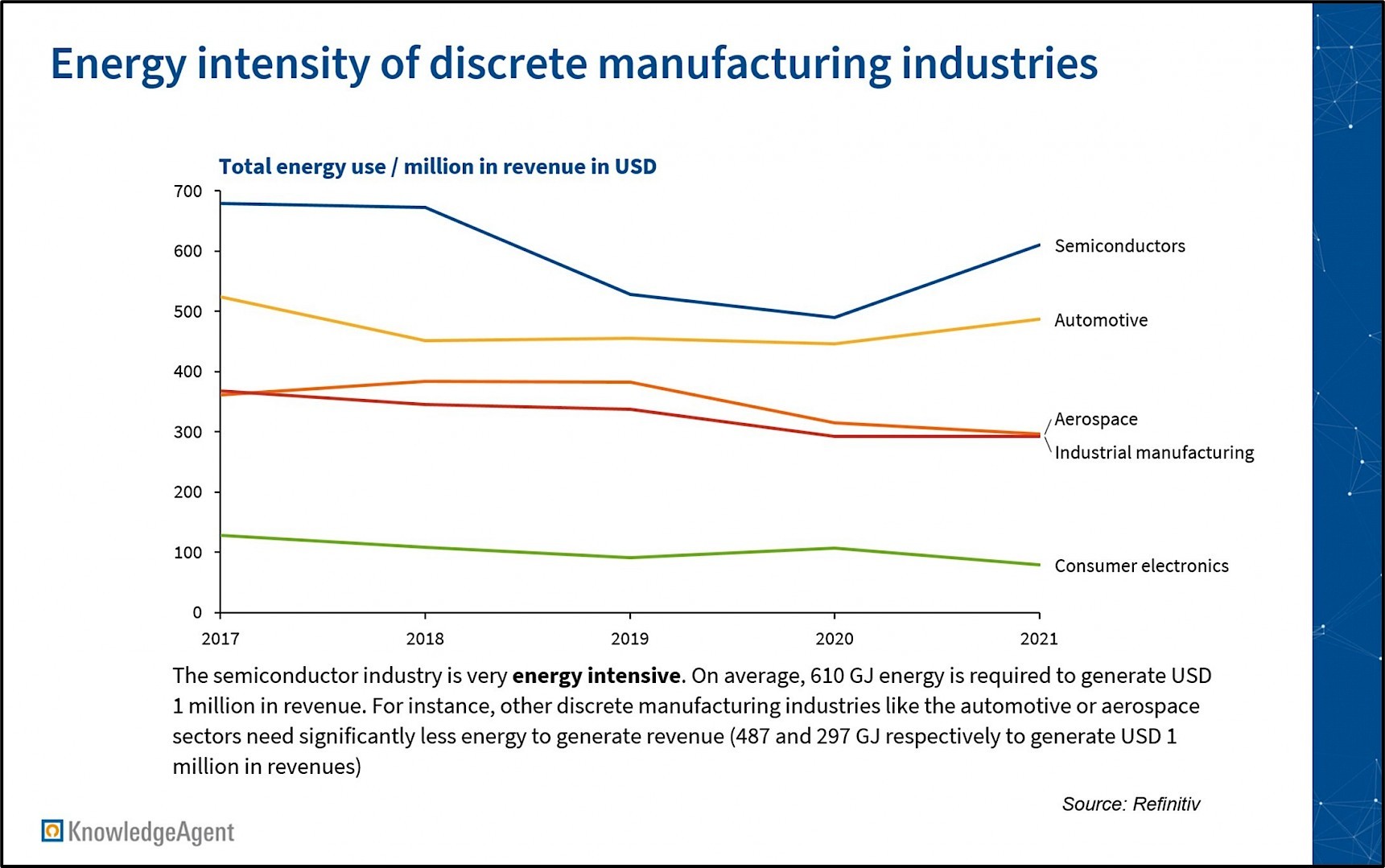

All leading manufacturers implemented strategies to become more sustainable. Intel for example, wants to use 100% renewable energy for its global operations by 2030 and achieve net zero GHG emissions (scope 1&2) by 2040.

The KnowledgeAgent Team prepared a short case study analysing Intel’s sustainability performance and targets along the value chain. The group has broad measures in place but lacks some tight scope 3 emission reduction targets. Nevertheless, benchmarking the group’s performance against its peers shows that Intel is a leading advocate of sustainability measures in the semiconductor industry.

Our exemplary sustainable value chain analysis and peer benchmarking of Intel is available for download.

Contact our team to find out more about our expertise and to assess how we can help you move your business in a sustainable future.

Sources:

-

United States Environmental Protection Agency (EPA) website, https://www.epa.gov/f-gas-partnership-programs/semiconductor-industry, accessed 1/8/2023

-

Semiconductor Digest, 24/10/2022, Water Supply Challenges for the Semiconductor Industry, https://www.semiconductor-digest.com/water-supply-challenges-for-the-semiconductor-industry/, accessed 1/8/2023

-

McKinsey & Company, 17/5/2022, Sustainability in semiconductor operations: Toward net-zero production, https://www.mckinsey.com/industries/semiconductors/our-insights/sustainability-in-semiconductor-operations-toward-net-zero-production, accessed 1/8/2023

-

The Guardian, 18/9/2021, The computer chip industry has a dirty climate secret, https://www.theguardian.com/environment/2021/sep/18/semiconductor-silicon-chips-carbon-footprint-climate, accessed 1/8/2023